Modular Blocks & T‑Joist System

Reduce completion times on horizontal projects.

Modular Blocks & T‑Joist System

Reduce completion times on horizontal projects.

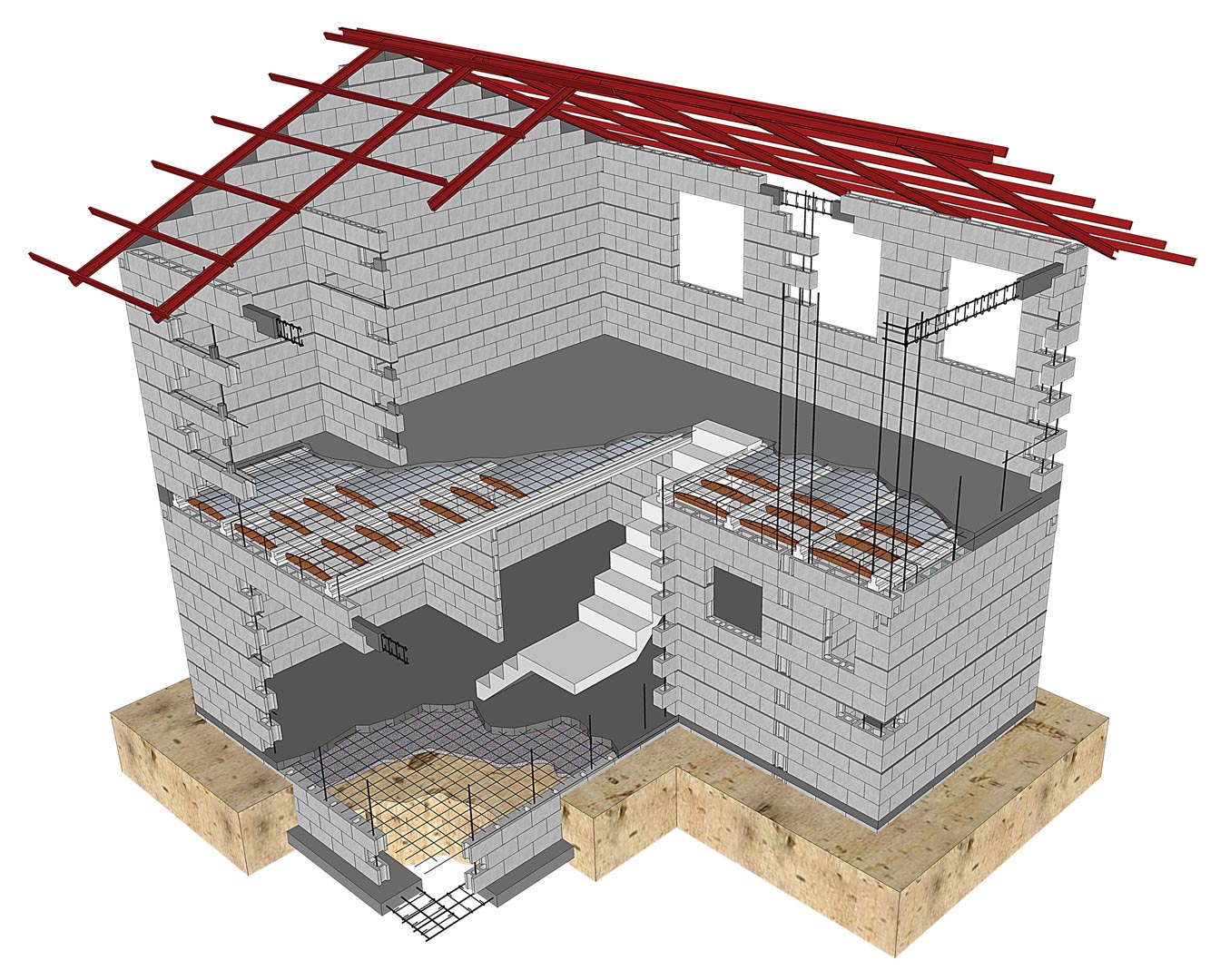

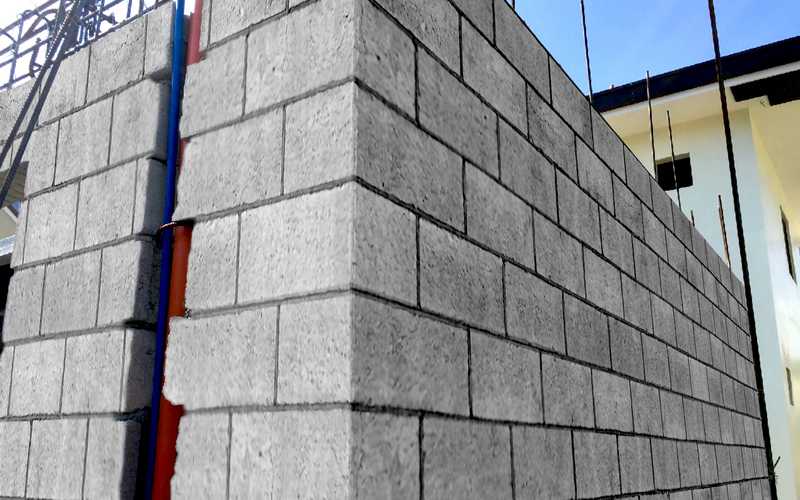

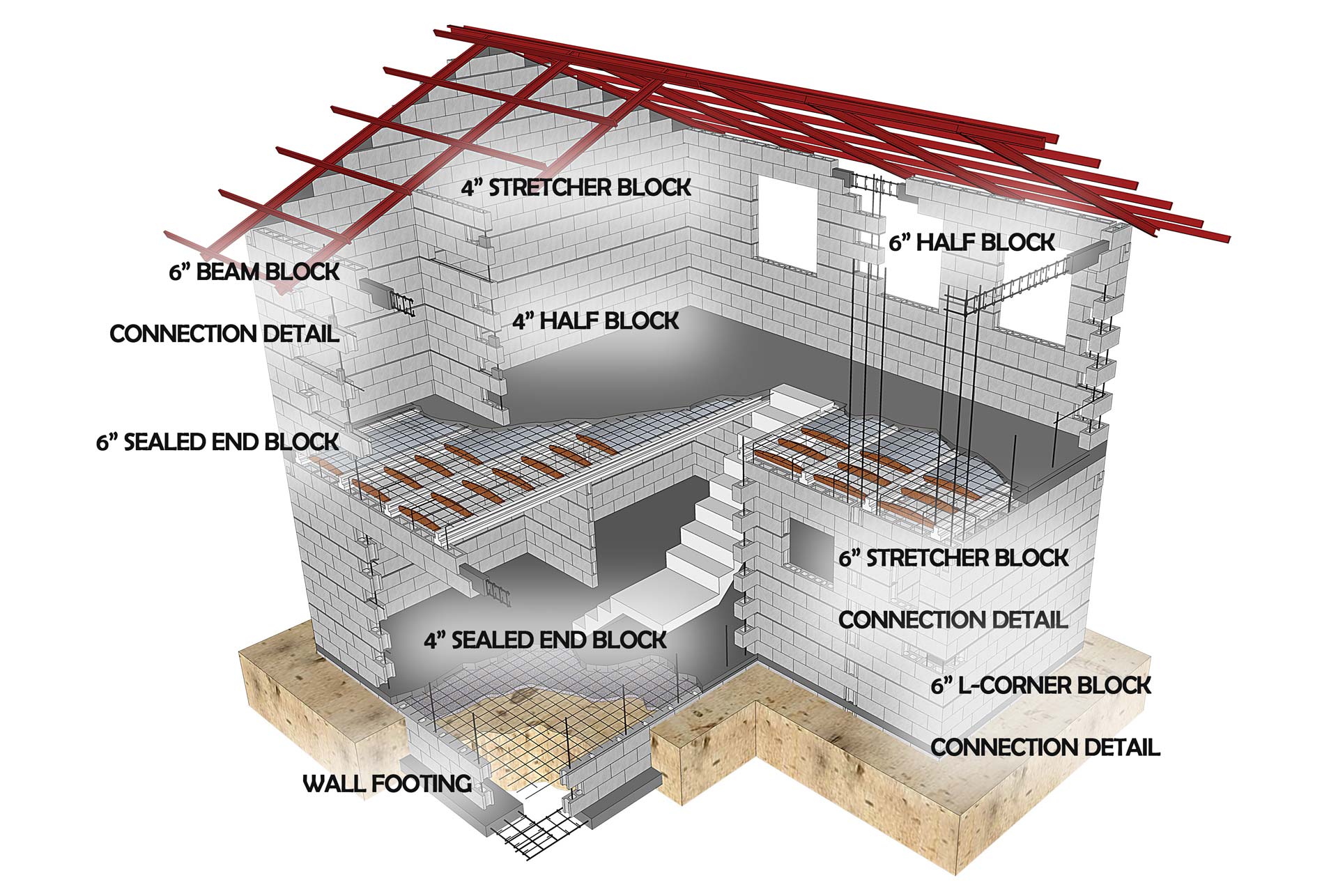

Jackbilt load-bearing modular blocks.

Jackbilt modular blocks speed up horizontal construction because they allow you to build houses without the need for cast-in-place columns or beams.

Typical Applications

Save on forms and concrete. Save time and money.

Mouse over or tap each pin to learn more.

As fast as 7 days – that’s how fast you can finish masonry work on a 30-square meter one-story single-detached house when you use Jackbilt modular blocks.

Partial grouting only on core holes with vertical reinforcement.

Less plastering needed compared to regular hollow blocks. Jackbilt blocks have a smooth surface finish.

Highly compacted with low water absorption rate.

For more information about

Modular Blocks

Modular Blocks & T‑Joist Floor System

Typical Installation

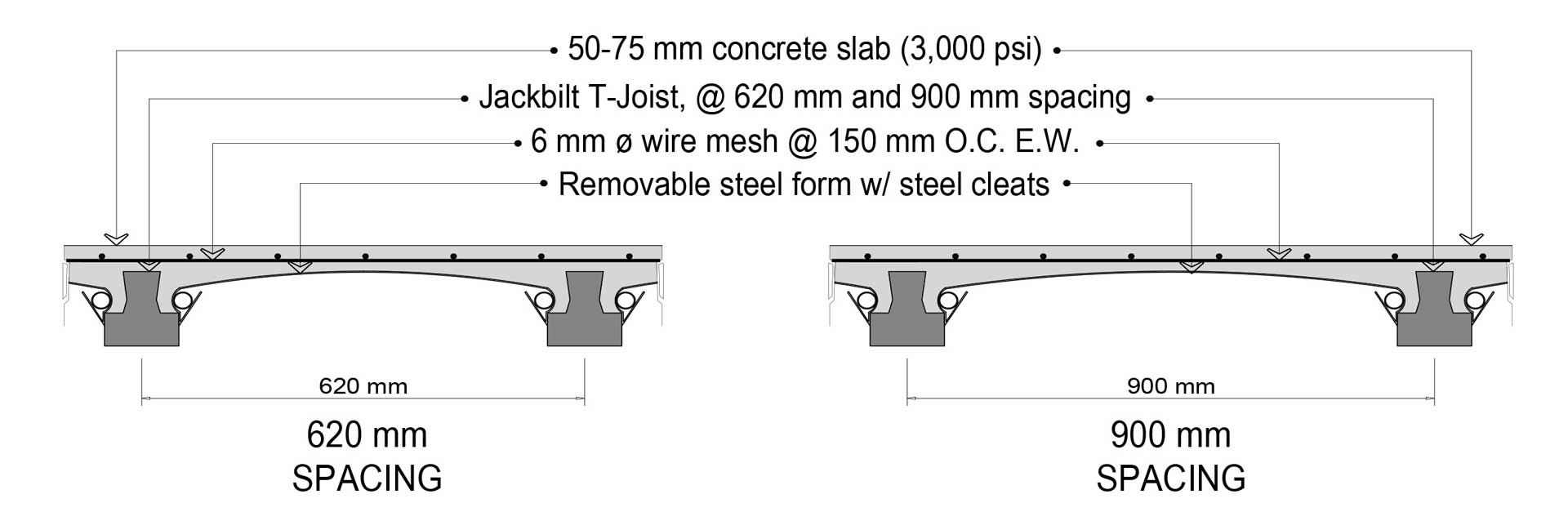

T‑JOISTS. Easy to install. No special equipment needed.

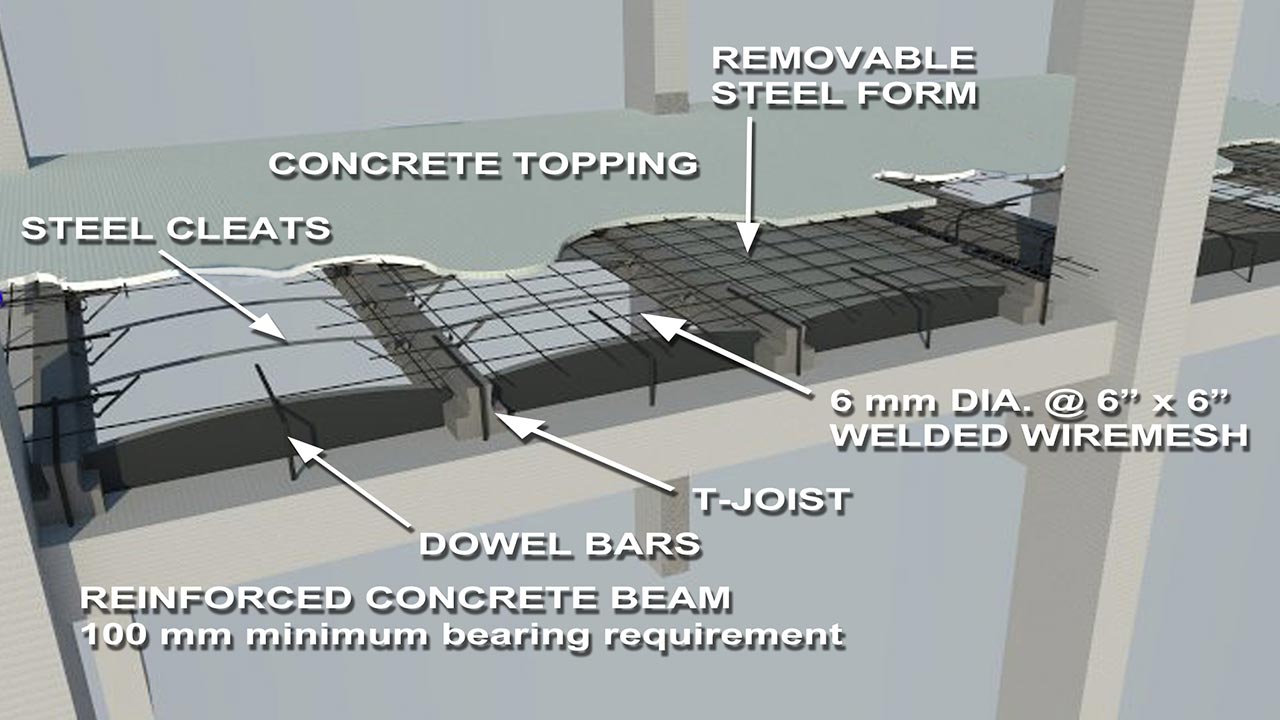

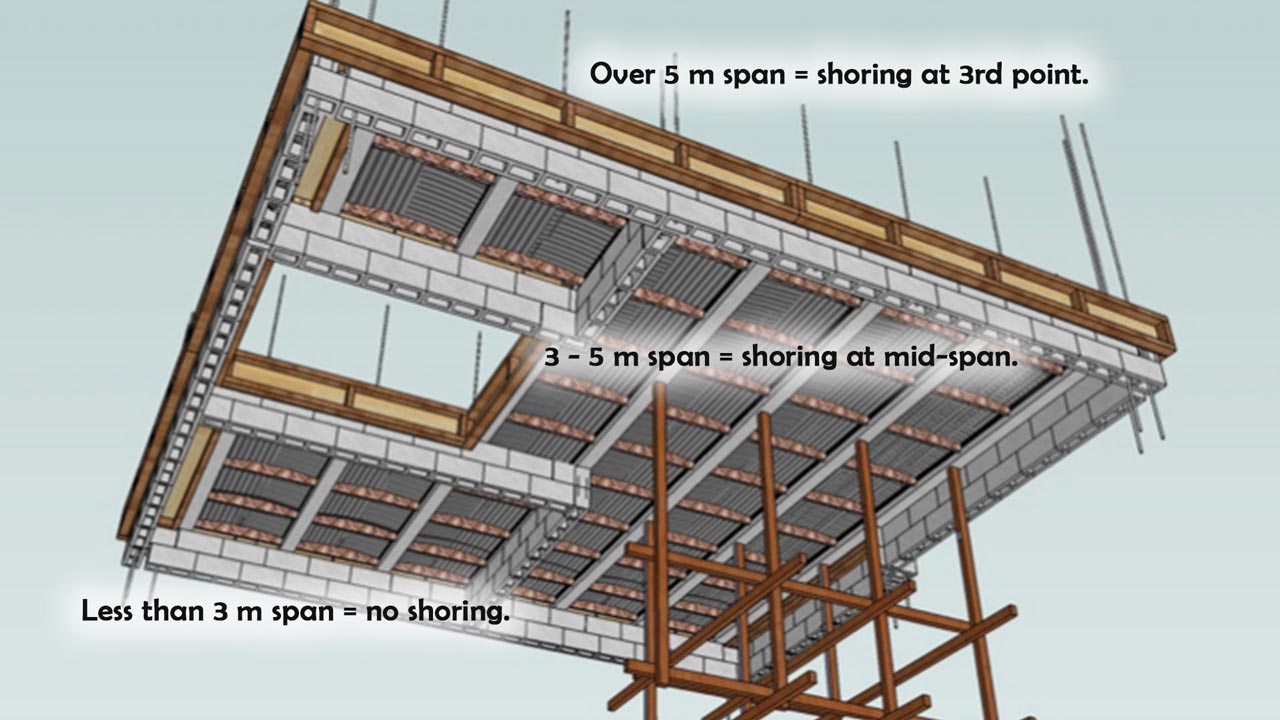

T-joists are precast, prestressed inverted T-beams that eliminate the need to install and dismantle labor-intensive plywood formworks for floor slab construction. No special equipment needed to install T-joists. They’re light enough to be carried by two workers.

T‑JOISTS. Easy to install. No special equipment needed.

T-joists are precast, prestressed inverted T-beams that eliminate the need to install and dismantle labor-intensive plywood formworks for floor slab construction. No special equipment needed to install T-joists. They’re light enough to be carried by two workers.

Technical Specifications

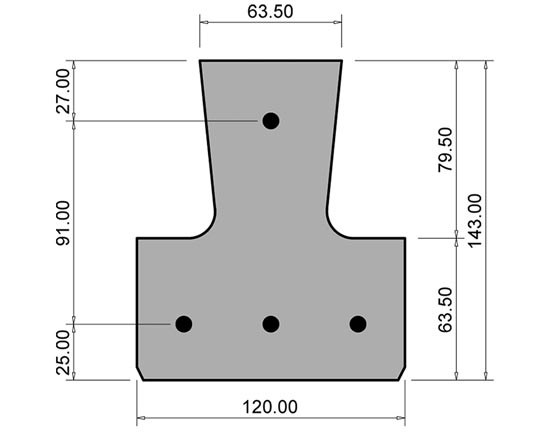

T‑Joist Cross Section

| CROSS SECTIONAL PROPERTIES | |

|---|---|

| Width, mm | 120 |

| Total height, mm | 143 |

| Cross section net area, mm2 | 12,561 |

| Distance top fiber to neutral axis (ytop), mm | 85 |

| Distance bottom fiber to neutral axis (ybot), mm | 58 |

| Moment of inertia (Ix) mm4 | 20 x 106 |

| Self weight (kgs/lineal m) | 30 |

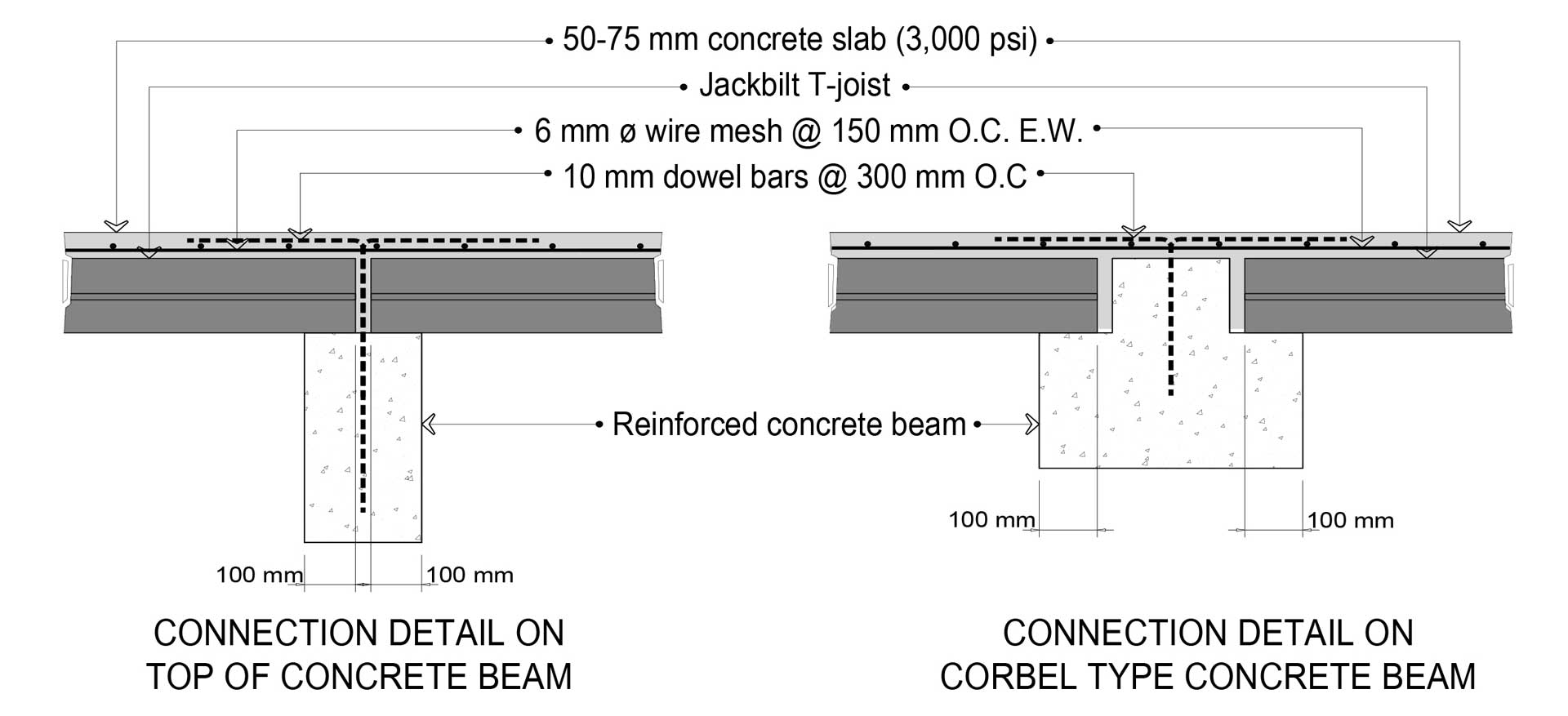

| DESIGN CONSIDERATIONS | |

|---|---|

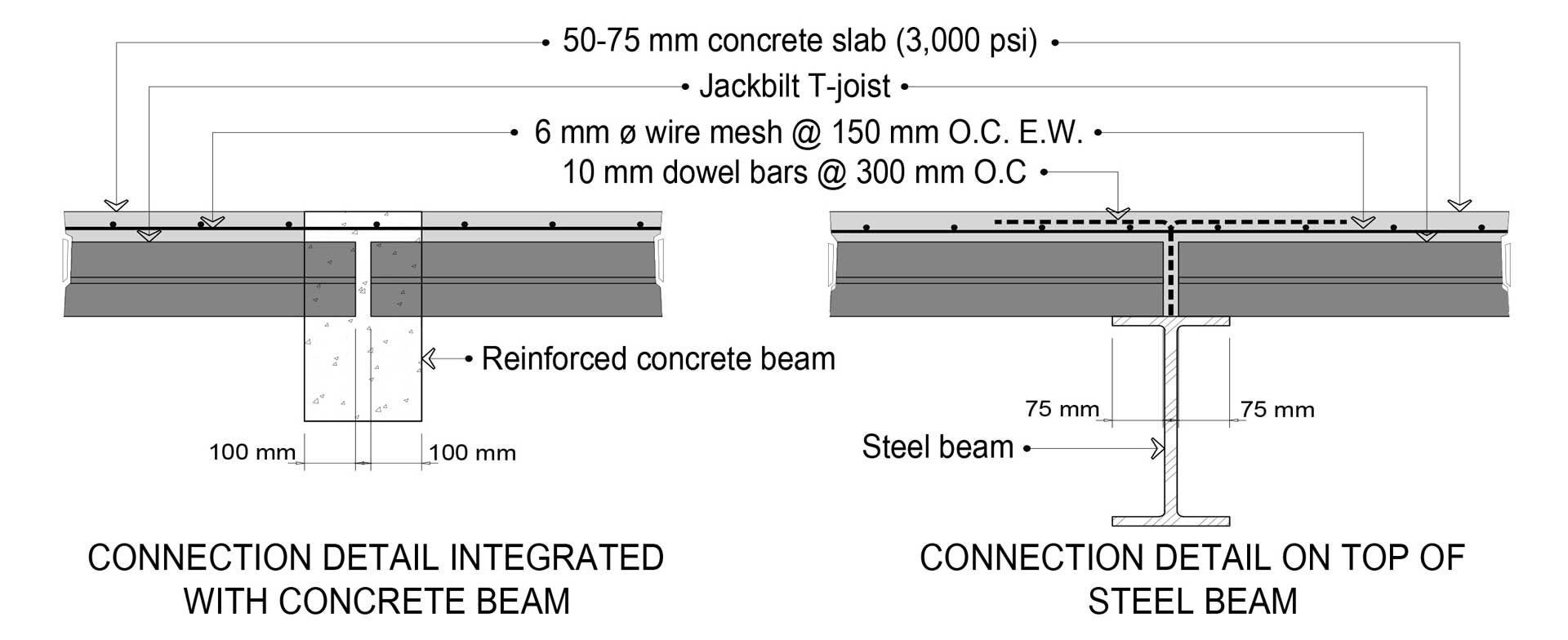

| Minimum bearing requirement - concrete beam, mm | 100 |

| Minimum bearing requirement - steel beam, mm | 75 |

| Superimposed dead load, kPa | 2 |

| CONCRETE PROPERTIES | |

|---|---|

| Concrete density, kg/m3 | 2,400 |

| Strength @ 28 days, f’c, MPa | 31 |

| Strength @ release, f’ci, MPa | 27 |

| Modulus of elasticity @ service, Ec, MPa | 30,094 |

| PRESTRESSING STEEL (stranded wire properties) - 6mm | |

|---|---|

| Nominal diameter mm | 6 |

3-wires, stress relieved, high tensile strands | |

| Ultimate strength, fpu, MPa | 1,860 |

| Yield strength, fpy, MPa | 1,582 |

| Modulus of elasticity, Ep, MPa | 186 x 103 |

| Area of wire, Ap, mm2 | 21 |

| PRESTRESSING STEEL (stranded wire properties) - 9mm | |

|---|---|

| Nominal diameter mm | 9 |

7-wires, low relaxation, high tensile strands | |

| Ultimate strength, fpu, MPa | 1,860 |

| Yield strength, fpy, MPa | 1,630 |

| Modulus of elasticity, Ep, MPa | 195 x 103 |

| Area of wire, Ap, mm2 | 55 |

| CONCRETE SLAB TOPPING | |

|---|---|

| Min. compressive strength @ 28 days, f’c, MPa | 21 |

| Slab topping thickness, mm | 50, 75 |

| Volume 50 mm concrete slab, m3/m2 | 0.080 |

| Volume 75 mm concrete slab, m3/m2 | 0.105 |

| Wire mesh reinforcement 6 mm ø at 150 mm o.c. | |

| Weight of steel reinforcement kg/m2 | 4 |

| DESIGN CONSIDERATIONS | |

|---|---|

| Minimum bearing requirement - concrete beam, mm | 100 |

| Minimum bearing requirement - steel beam, mm | 75 |

| Superimposed dead load, kPa | 2 |

| PRESTRESSING STEEL (stranded wire properties) | ||

|---|---|---|

| Nominal diameter mm | 6 | 9 |

| Wires (high tensile strands) | 3-wires, stress relieved | 7-wires, low relaxation |

| Ultimate strength, fpu, MPa | 1,860 | 1,860 |

| Yield strength, fpy, MPa | 1,582 | 1,630 |

| Modulus of elasticity, Ep, MPa | 186 x 103 | 195 x 103 |

| Area of wire, Ap, mm2 | 21 | 55 |

T‑Joist

Typical Installation