J-Wall Partition Panels

7 times faster than traditional block work.

Easy-to-install, lightweight, non-load-bearing precast partition panels manufactured in the Philippines.

Fast forward project completion. Reduce material and labor costs.

Typical Applications

Plus security or perimeter fences, hospitals, service flats, townhouses, and tract housing.

Technical Specifications

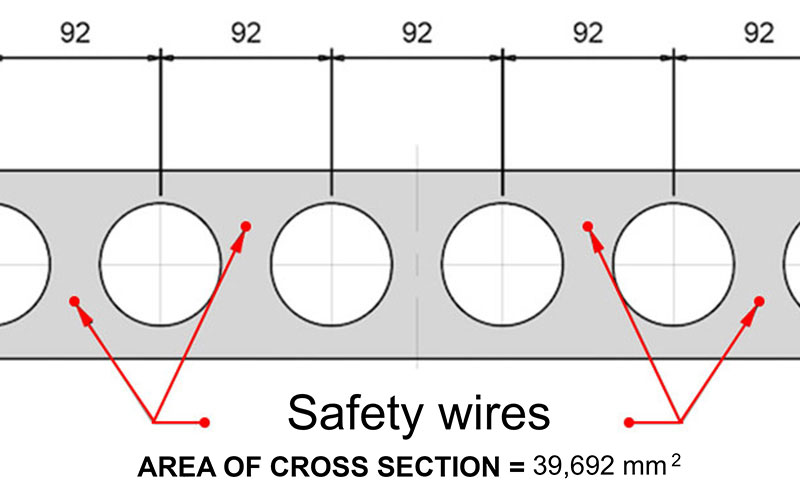

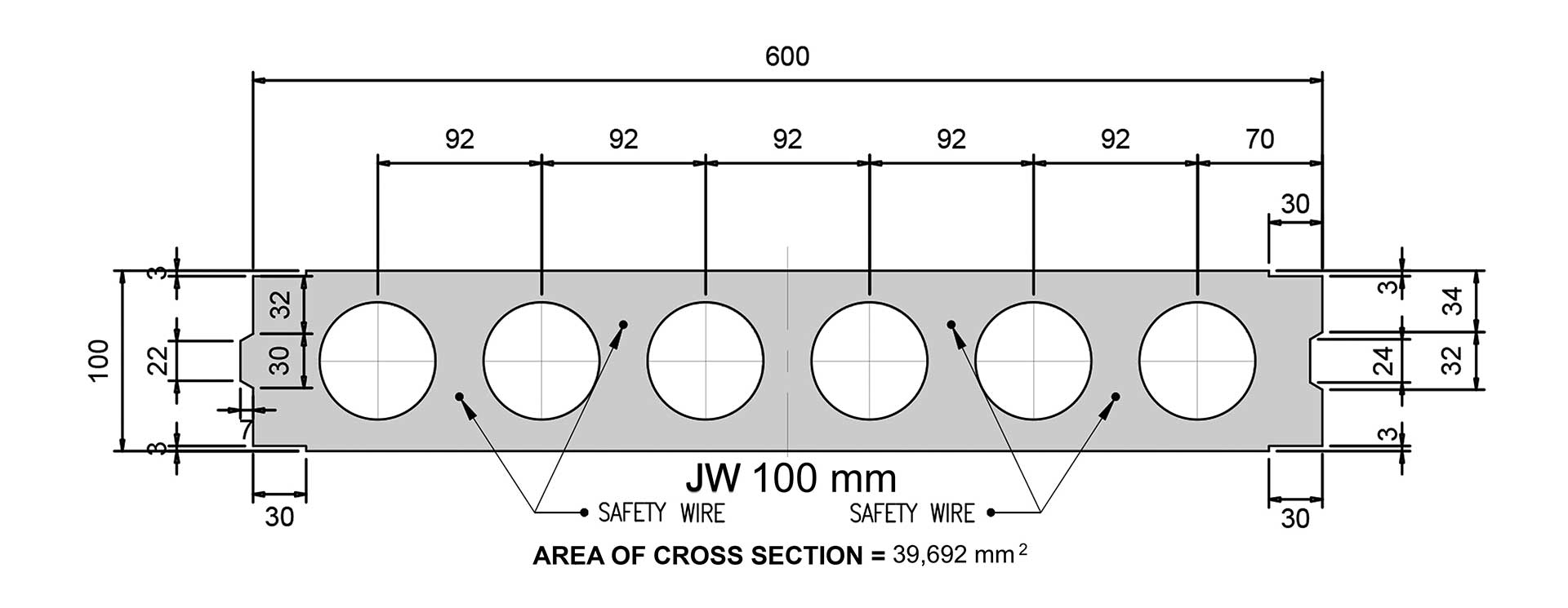

J-Wall Cross Section

| PROPERTIES | |

|---|---|

| Thickness mm | 100 |

| Width mm | 600 |

| Weight kg/m2 | 142 |

| Compressive strength psi 3x stronger than regular non-load-bearing blocks | 1,200 |

| Sound insulation dB | 41 |

| Fire resistance rating, hours | 2 |

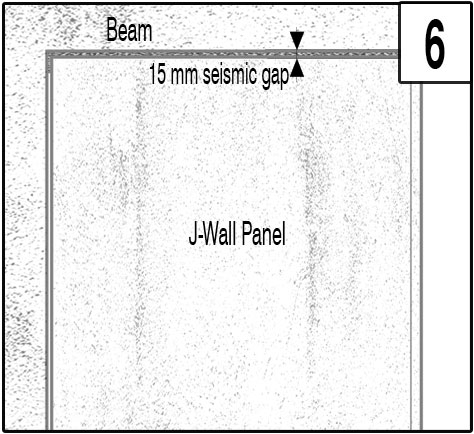

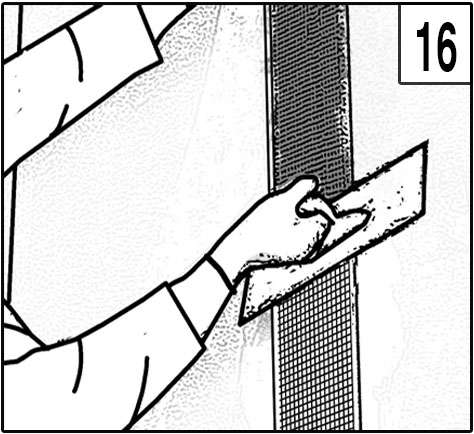

J-Wall Panel

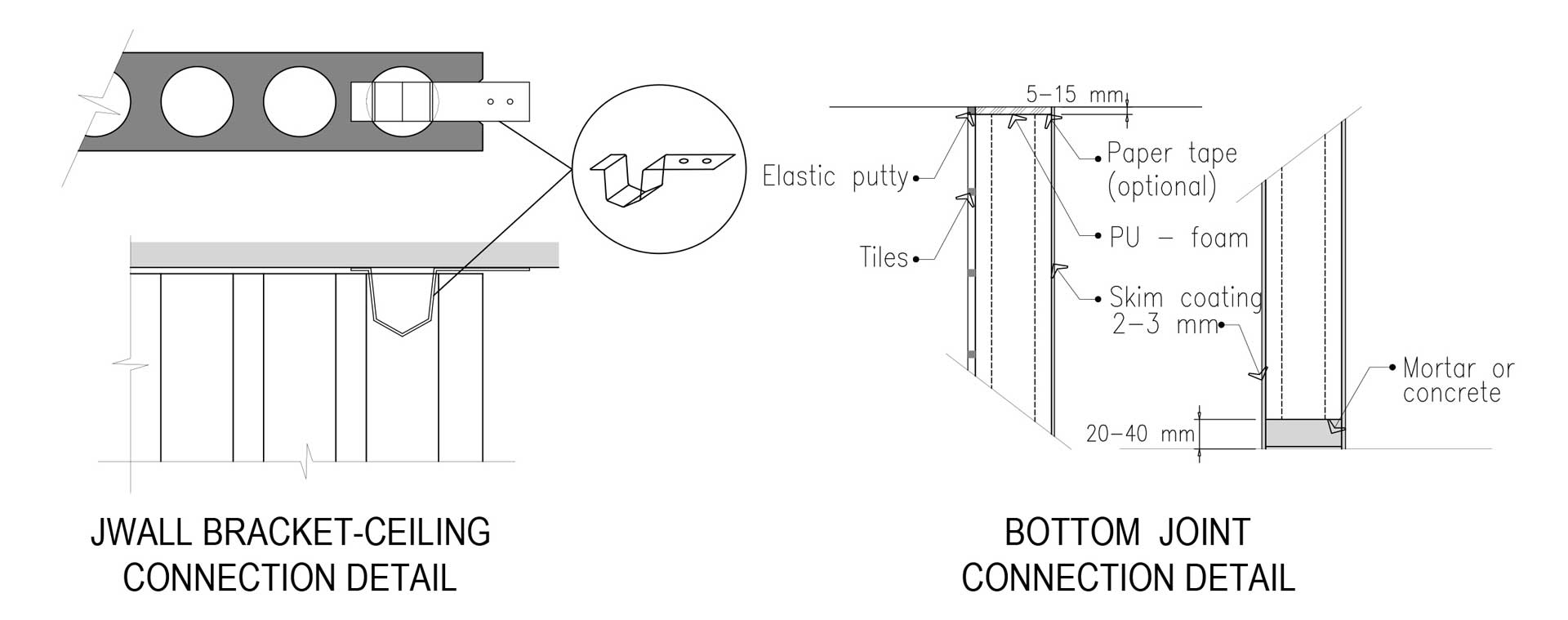

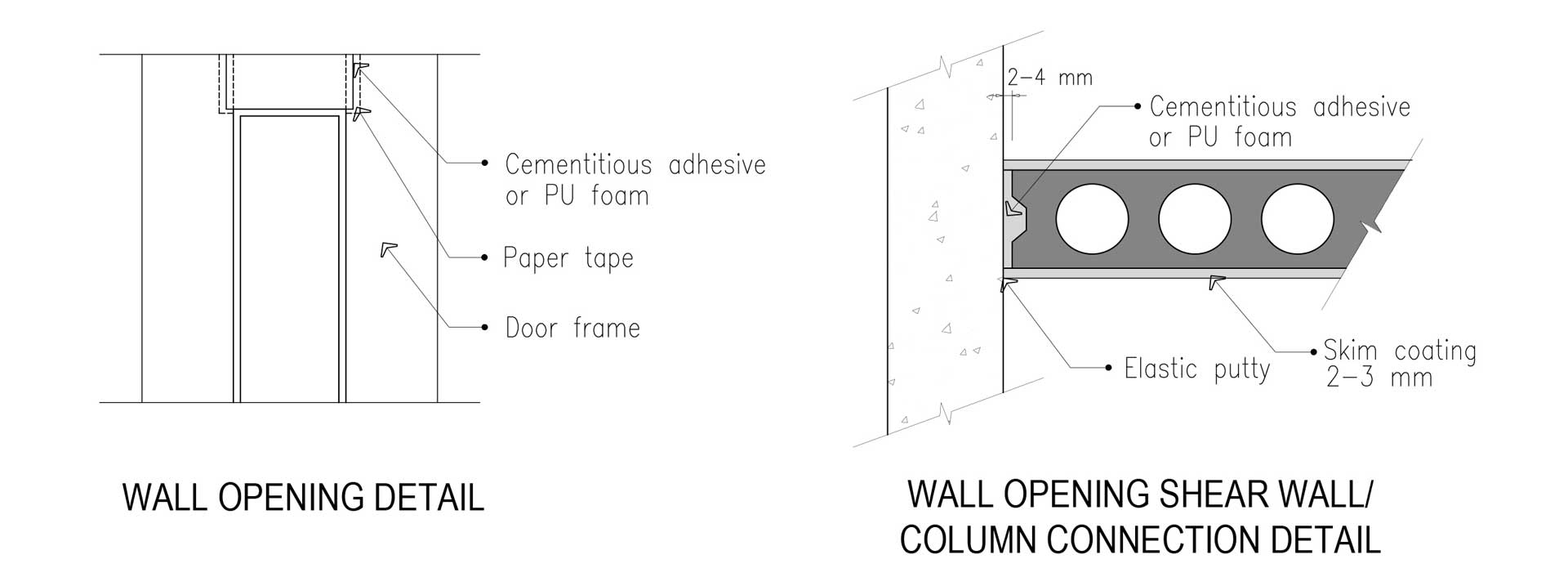

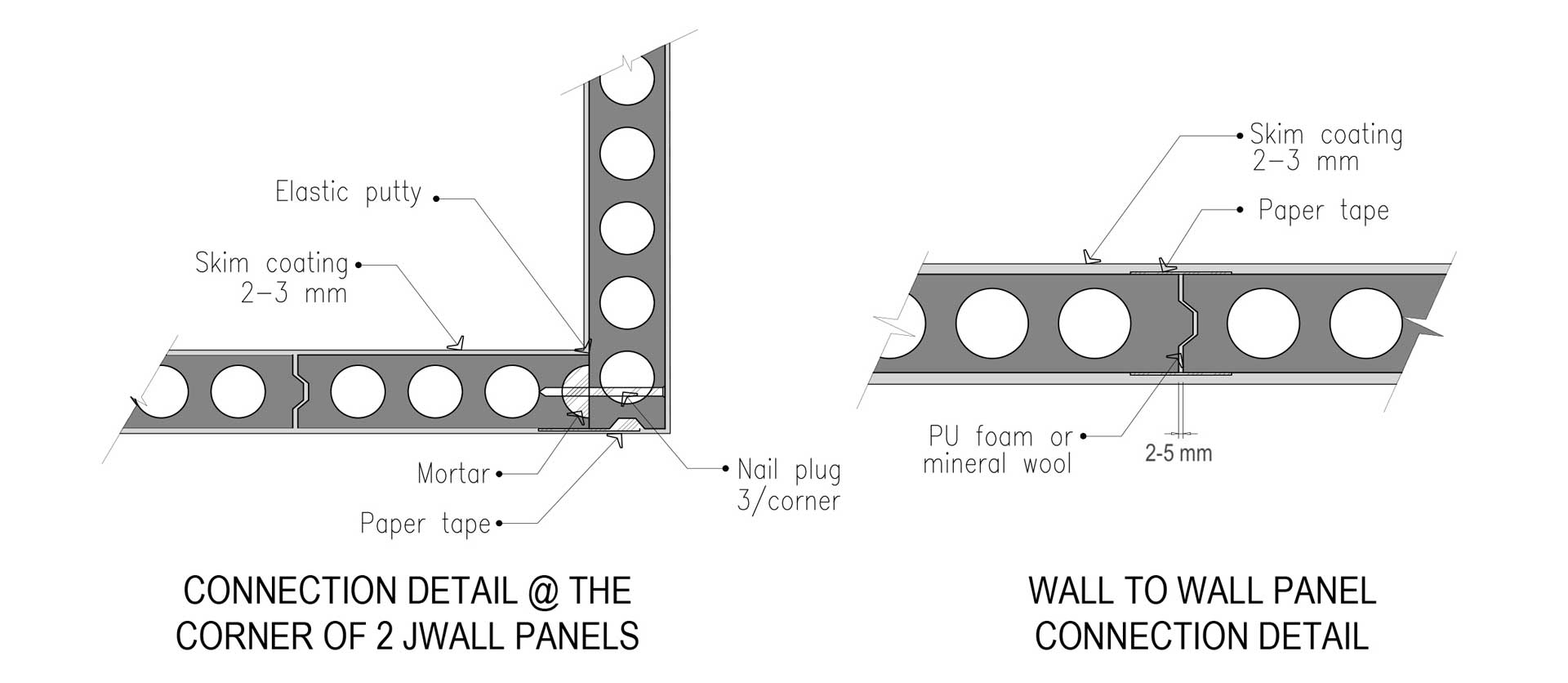

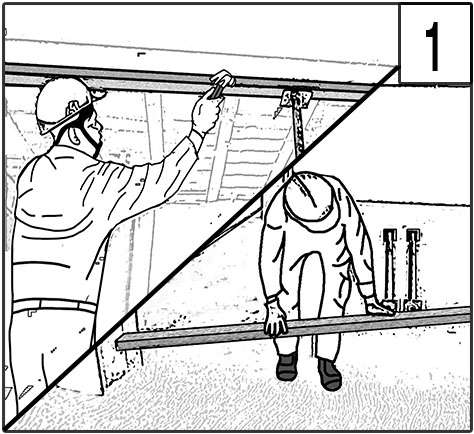

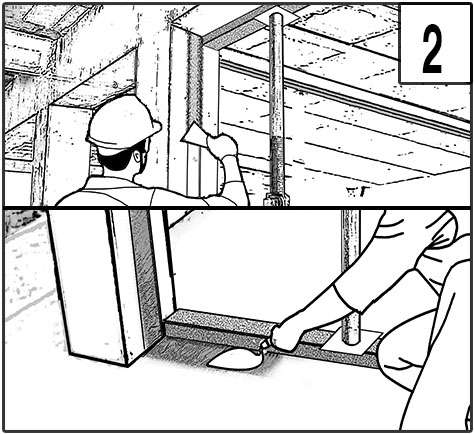

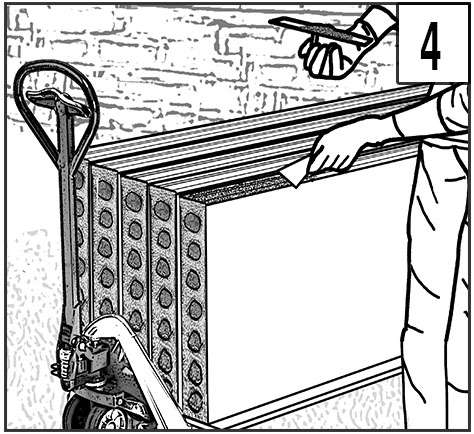

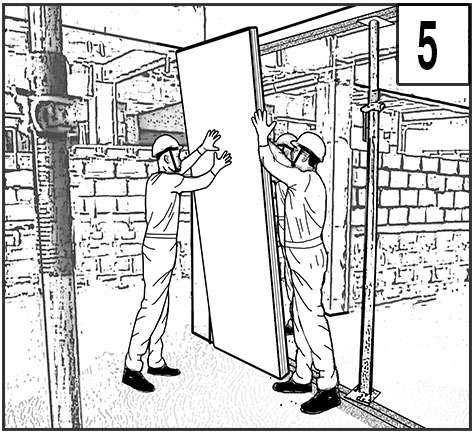

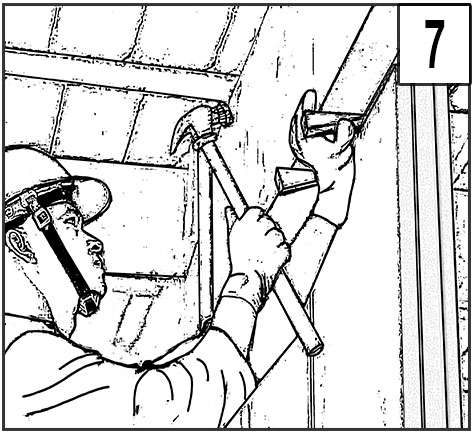

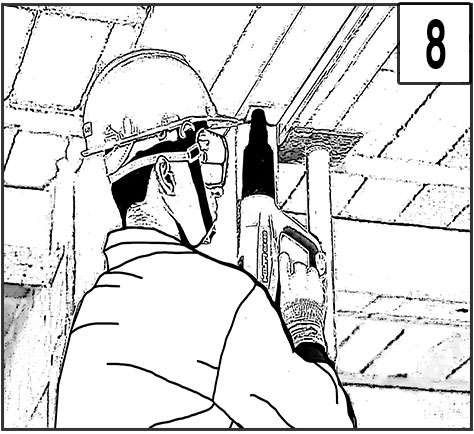

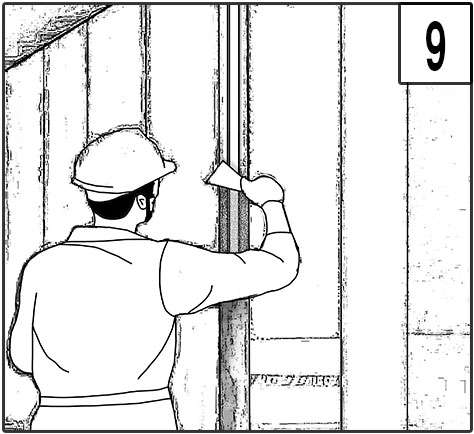

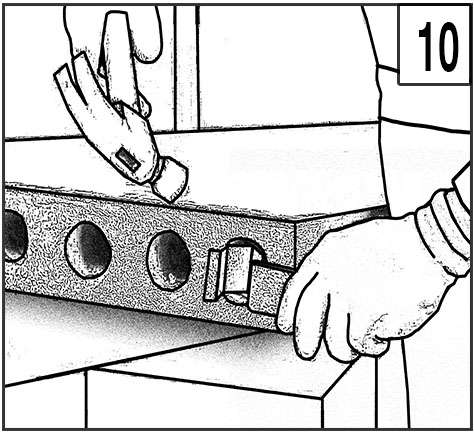

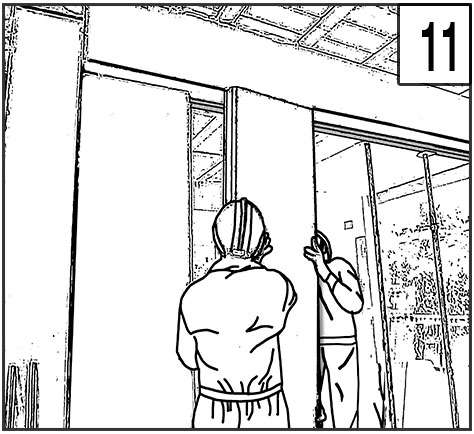

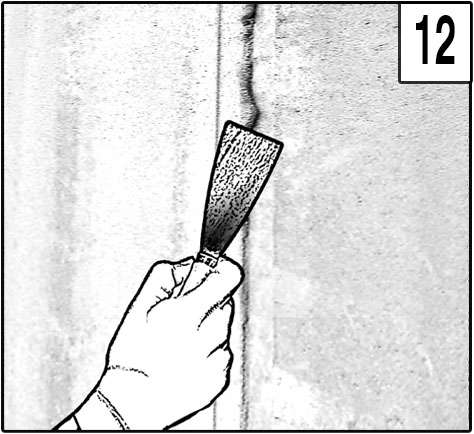

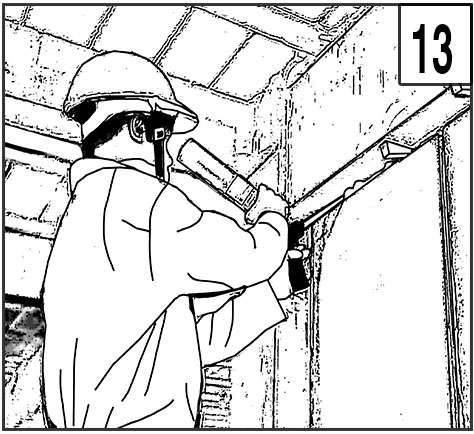

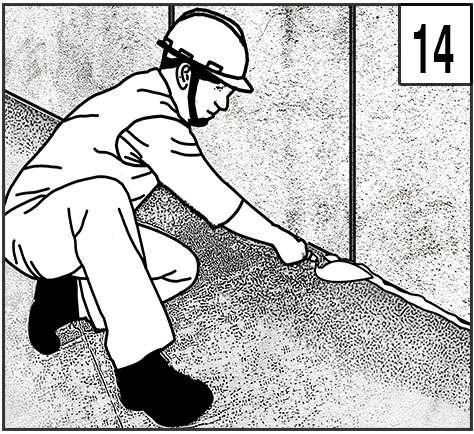

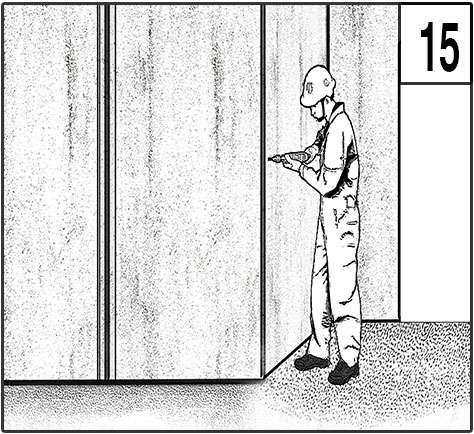

Installation