Ribbed Slabs & Half Slabs

Proven time-savers and cost-cutters.

Ribbed Slab

Ribbed Slab

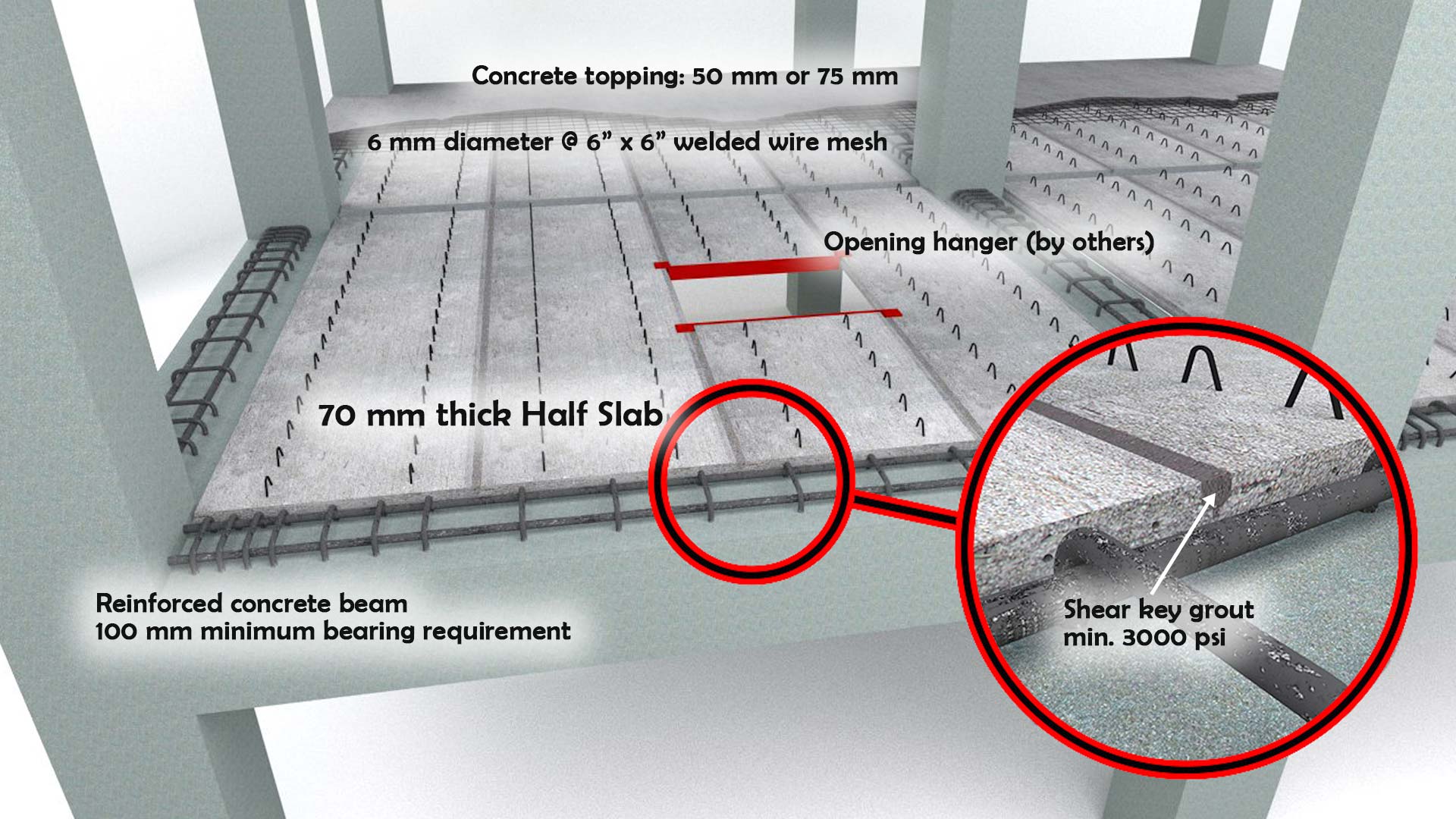

Half Slab

Half Slab

Typical Span: 3 – 4 meters

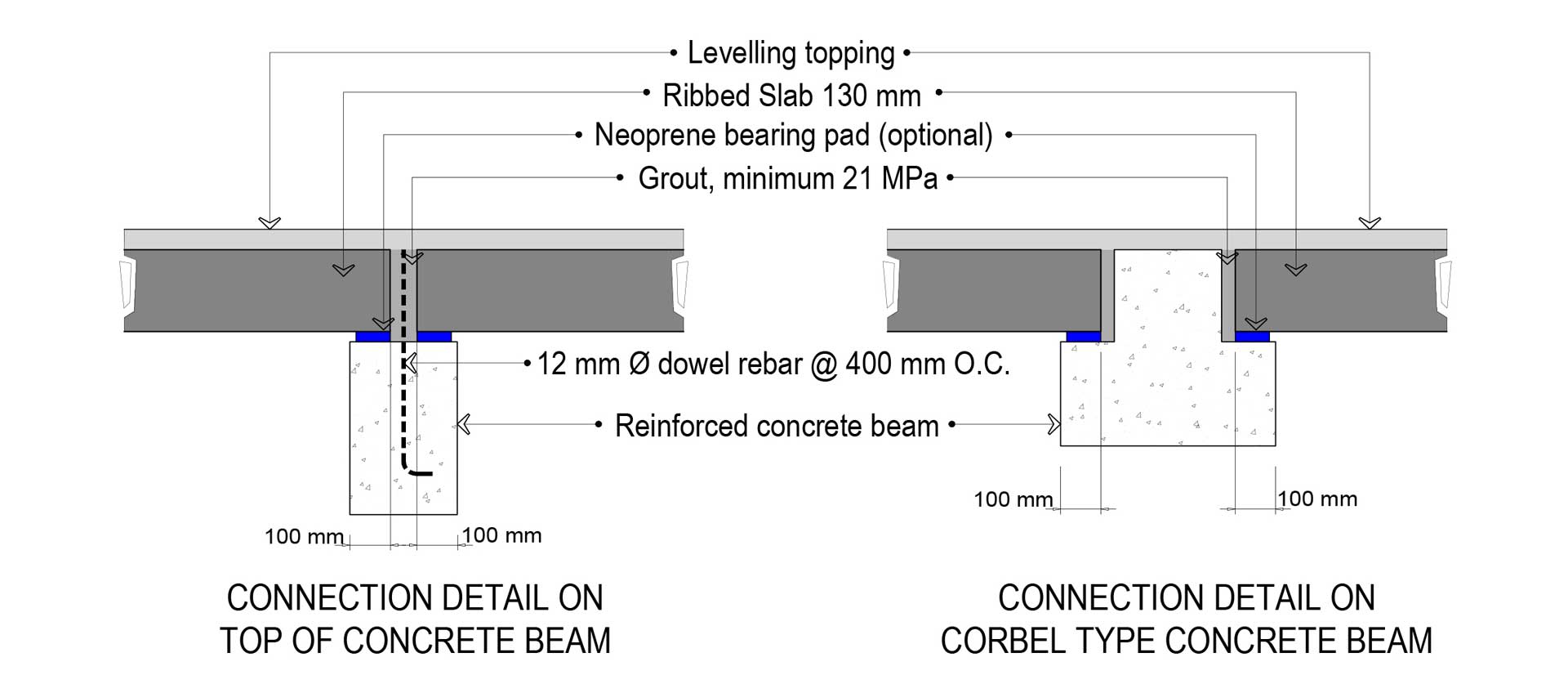

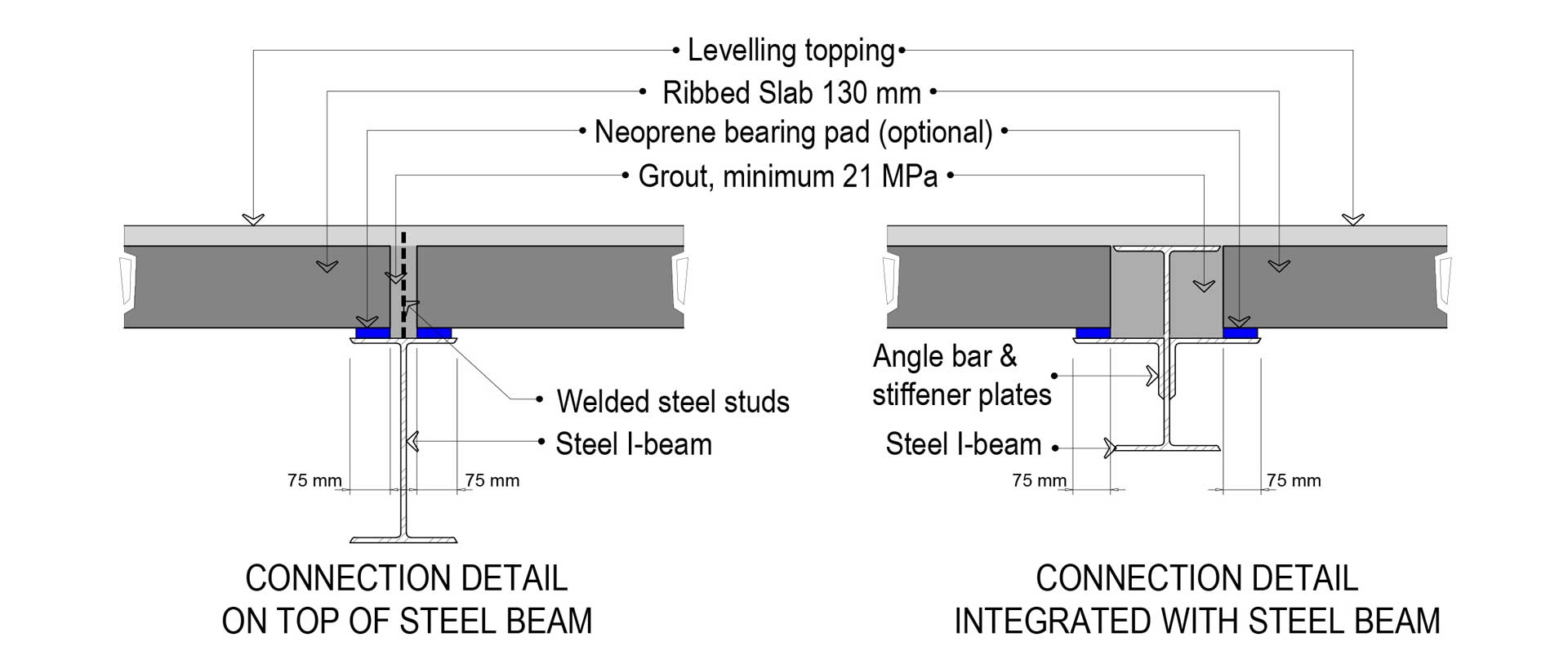

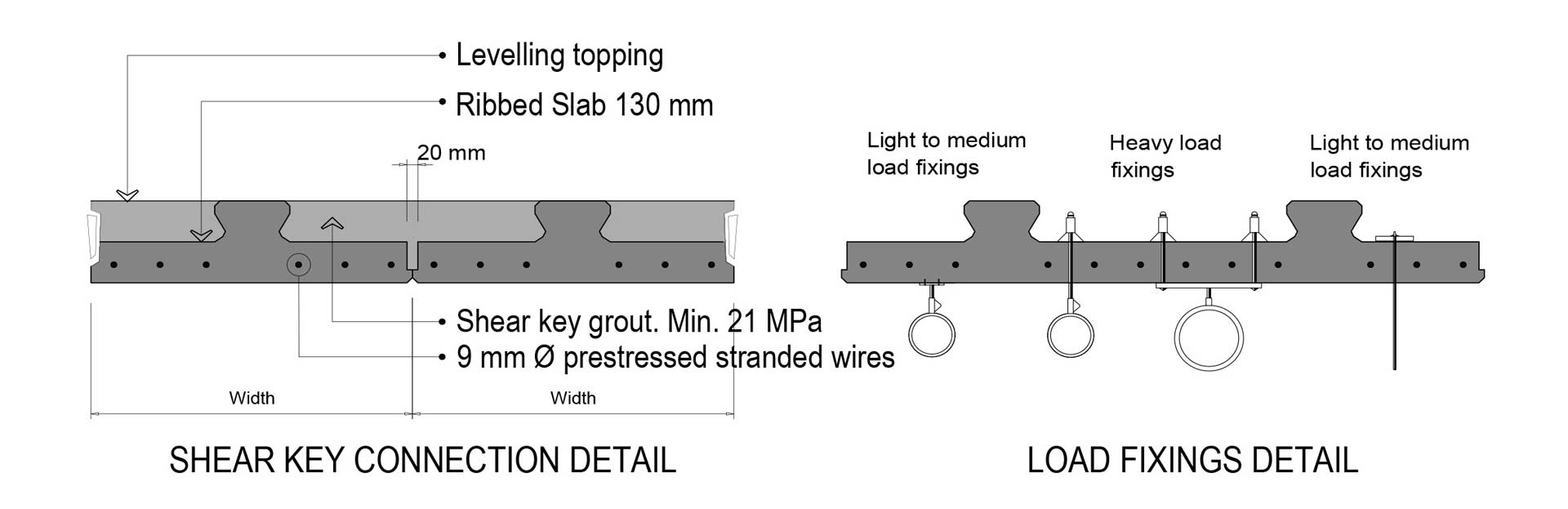

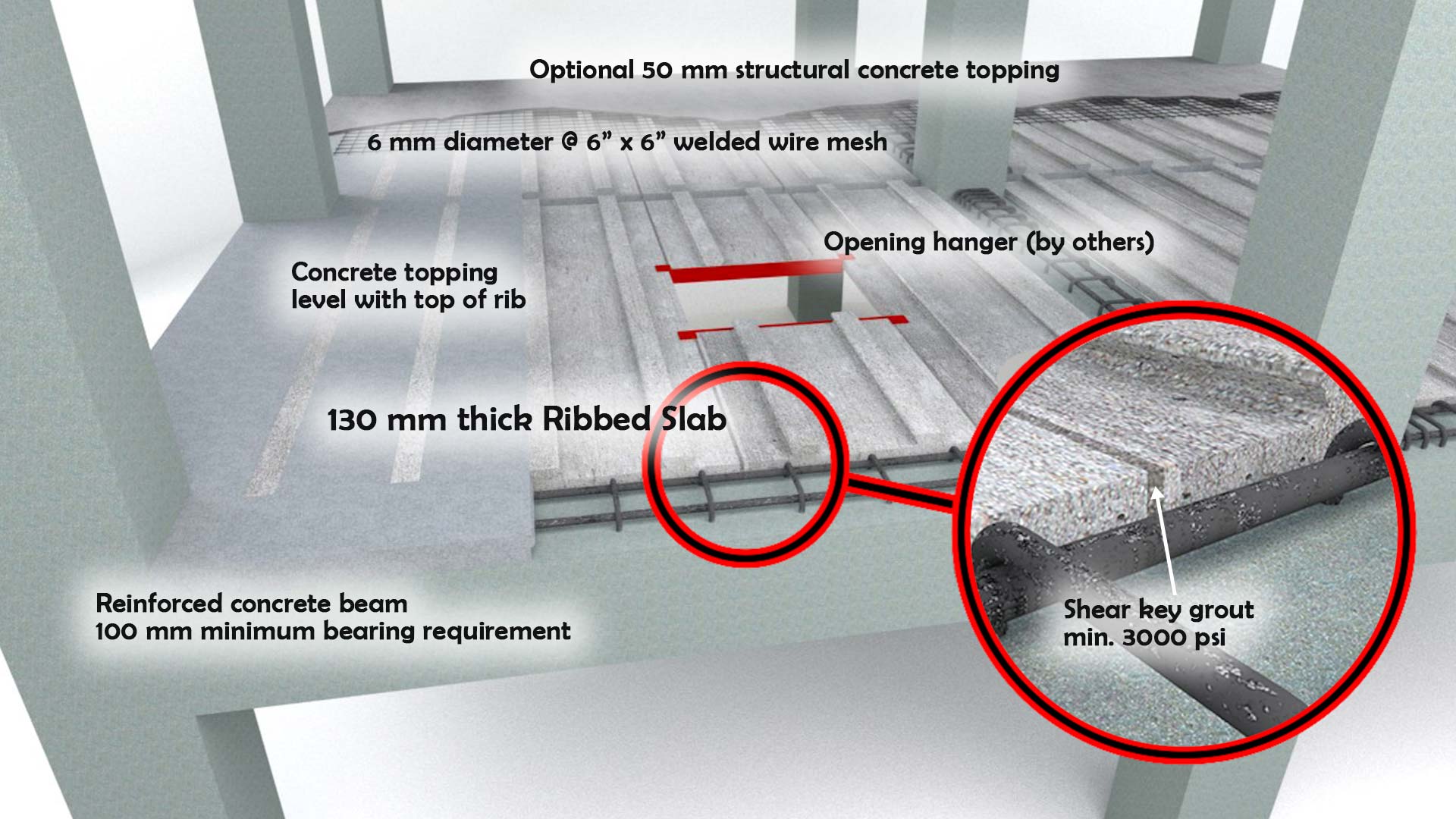

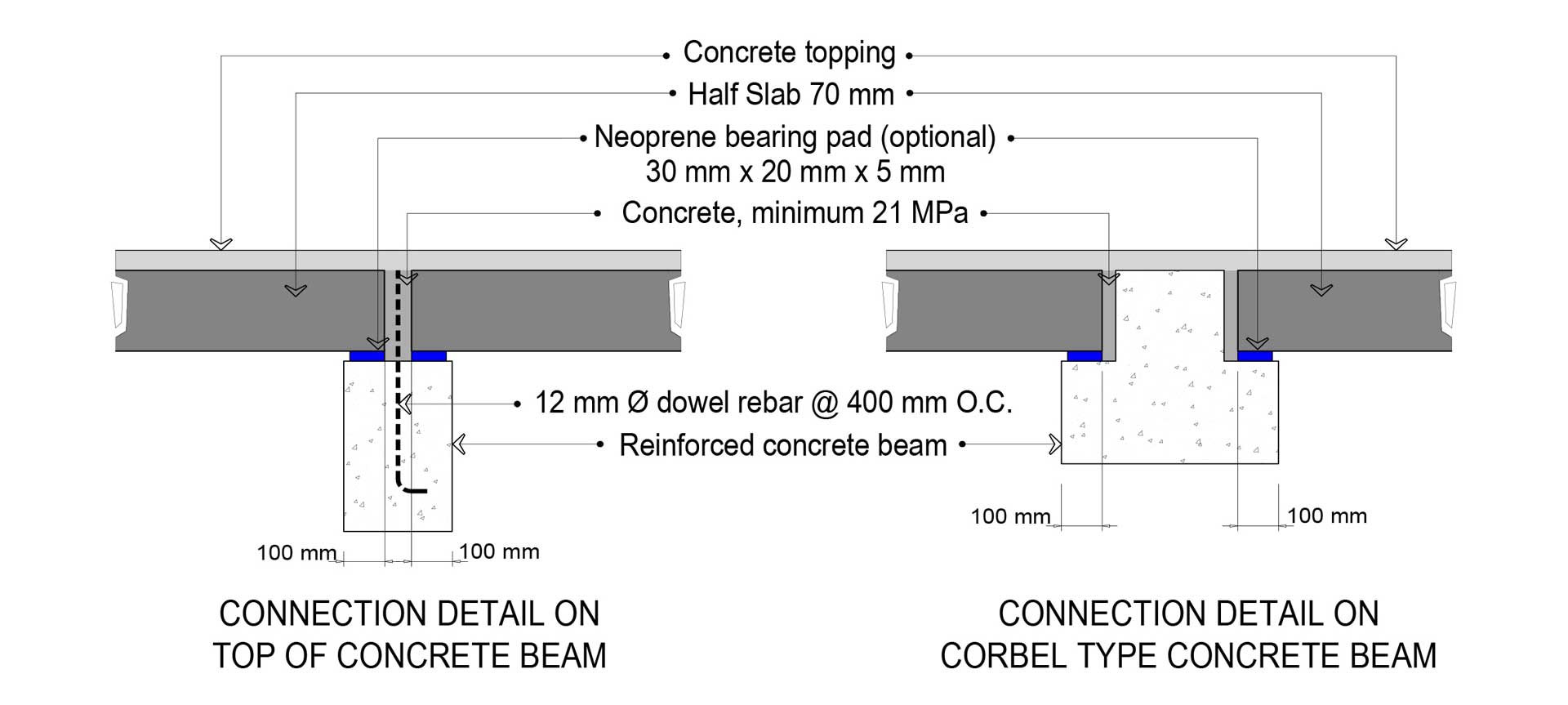

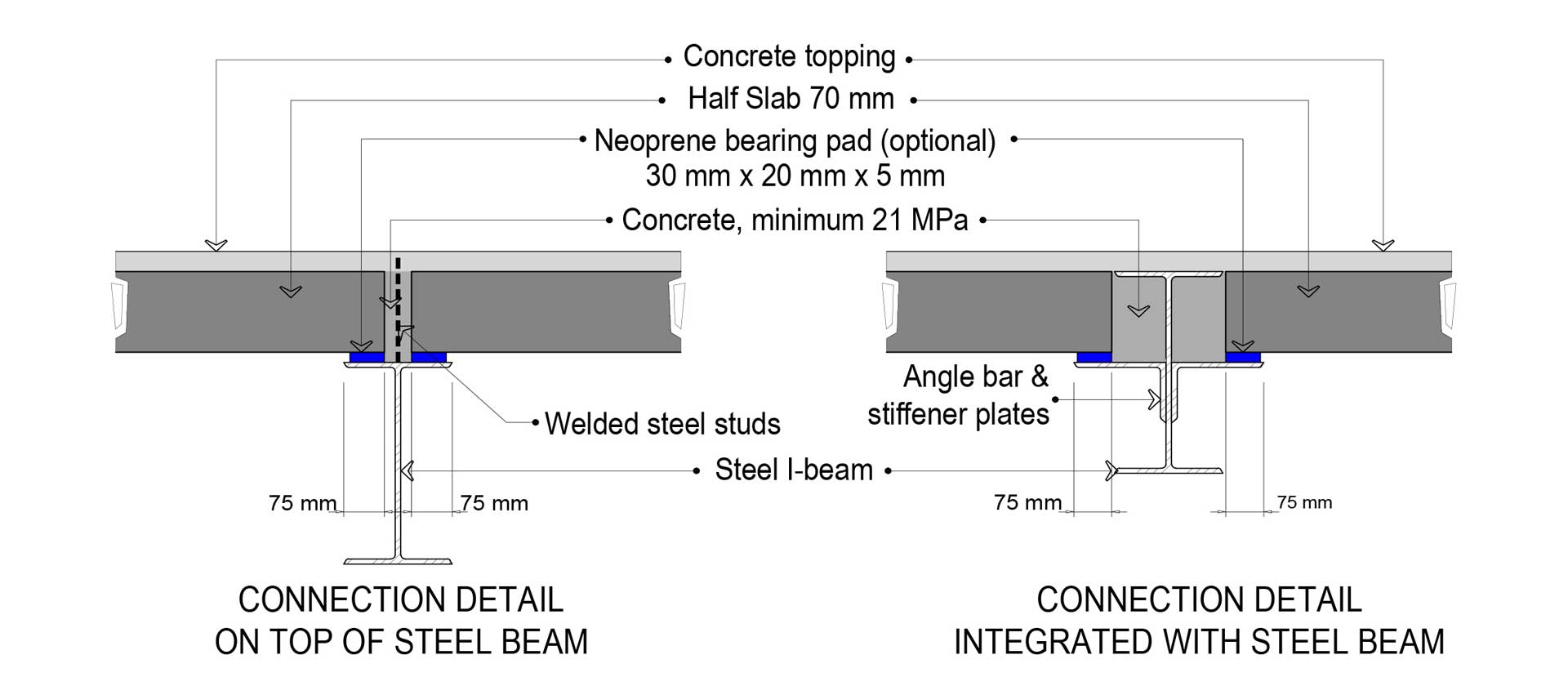

Jackbilt ribbed slabs and half slabs are proven time-savers and cost-cutters. The concrete upstands of ribbed slabs and the metal dowels of half slabs serve similar functions – they facilitate handling and installation and serve as positive ties between the slabs and concrete topping.

Only 1 shoring needed for every 3 meter span.

No need for drop ceilings.

Typical Applications

Speed, Ease, Efficiency.

Jackbilt half slabs speed up construction. No need to set up and dismantle formworks, shoring, and scaffolds.

– A.P. Canlas Builders

Speed, Ease, Efficiency.

Jackbilt half slabs speed up construction. No need to set up and dismantle formworks, shoring, and scaffolds.

– A.P. Canlas Builders

– A senior architect of Forte Realty

– A senior architect of Forte Realty

– Senior engineer, EEI

– Senior engineer, EEI

Technical Specifications

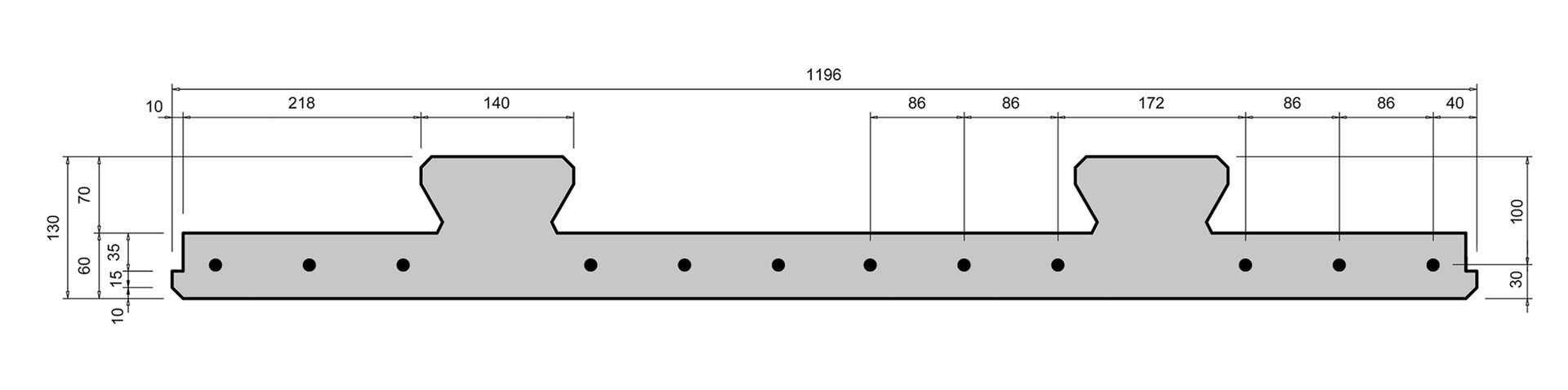

| CROSS SECTIONAL PROPERTIES | |

|---|---|

| Width mm | 1,196 |

| Height of plank mm | 60 |

| Cross section net area mm2 | 88,261 |

| Top fiber to neutral axis (Ytop) mm | 87 |

| Bottom fiber to neutral axis (Ybot) mm | 43 |

| Moment of inertia (lx) mm4 | 486 x 103 |

| Self weight of product, kg/m2 | 312 |

| CONCRETE PROPERTIES | |

|---|---|

| Concrete density, kg/m3 | 2,400 |

| Strength @ 28 days, MPa | 41 |

| Strength @ release, MPa | 28 |

| Modulus of elasticity @ service, Ec, MPa | 30 x 103 |

| PRESTRESSING STEEL | |

|---|---|

| 7 wires, high tensile, helical strand | |

| Ultimate strength, fpu, MPa | 1,860 |

| Yield strength, fpy, MPa | 1,630 |

| Modulus of elasticity, Ep, MPa | 195 x 103 |

| Nominal diameter, D mm | 9 |

| Area of wire, Ap mm2 | 55 |

| CONCRETE TOPPING |

|---|

| To produce a flat surface and solid slab section, provide concrete topping with a minimum strength @ 28 days, f’c, = 21 MPa (3,000 psi) in space between ribs. |

| To increase capacity of the ribbed slab, provide additional structural topping with a minimum strength @ 28 days, f’c, = 21 MPa (3,000 psi) of 50 mm from the top of rib. |

| Wire mesh reinforcement: 6 mm diameter at 150 mm o.c. |

For more information about

Ribbed Slabs

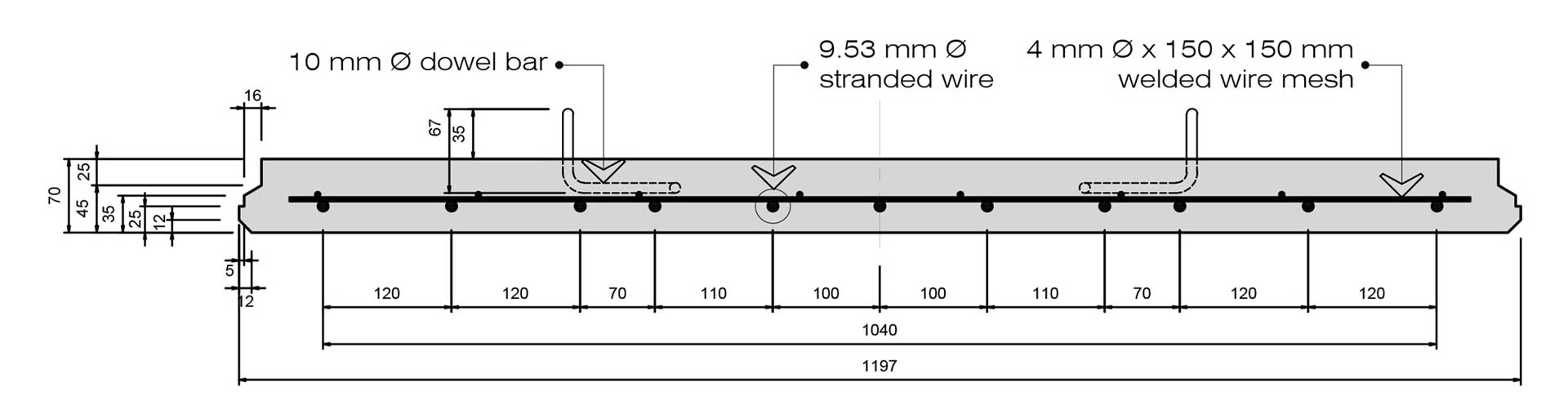

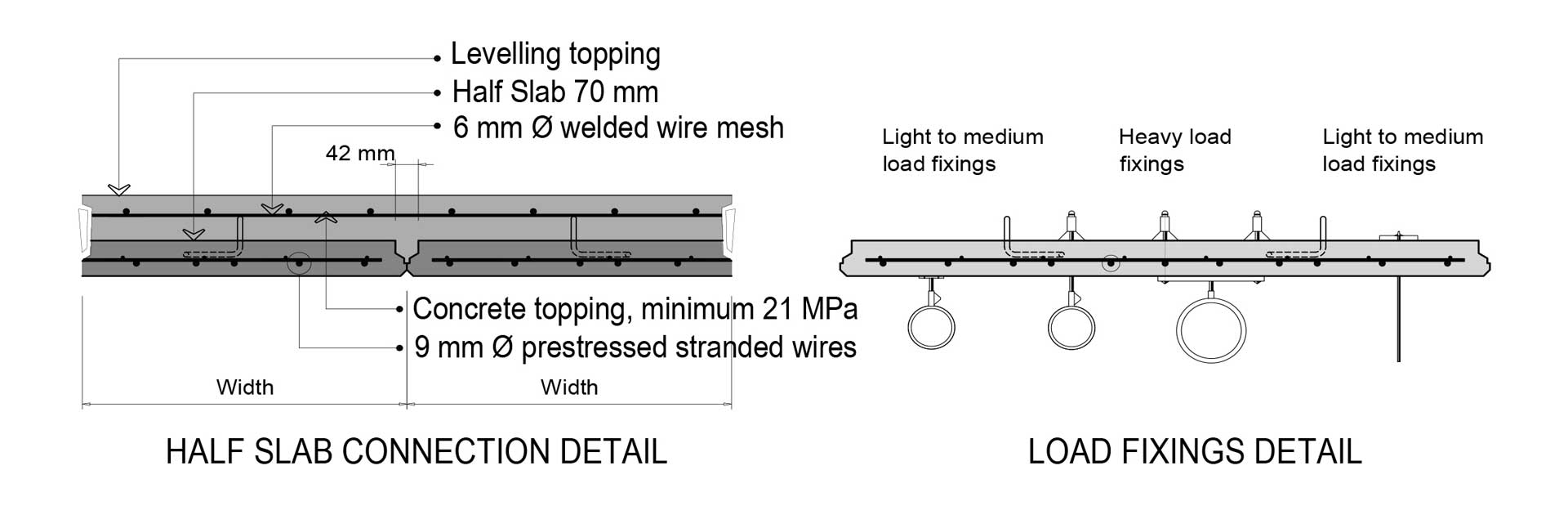

Technical Specifications

| CROSS SECTIONAL PROPERTIES | |

|---|---|

| Width mm | 1,197 |

| Height of plank mm | 70 |

| Cross section net area mm2 | 82,236 |

| Top fiber to neutral axis (Ytop) mm | 34 |

| Bottom fiber to neutral axis (Ybot) mm | 35 |

| Moment of inertia (lx) mm4 | 33 x 106 |

| Self weight of product, kg/m2 | 197 |

| CONCRETE PROPERTIES | |

|---|---|

| Concrete density, kg/m3 | 2,400 |

| Strength @ 28 days, MPa | 41 |

| Strength @ release, MPa | 27 |

| Modulus of elasticity @ service, Ec, MPa | 30 x 103 |

| PRESTRESSING STEEL | |

|---|---|

| 7 wires, high tensile, helical strand | |

| Ultimate strength, fpu, MPa | 1,860 |

| Yield strength, fpy, MPa | 1,630 |

| Modulus of elasticity, Ep, MPa | 195 x 103 |

| Nominal diameter, D mm | 9 |

| Area of wire, Ap mm2 | 55 |

| CONCRETE TOPPING |

|---|

| Provide concrete with a minimum strength @ 28 days, f’c, = 21 MPa with 50 mm height from top of plank. |

| Wire mesh reinforcement 6 mm diameter at 150 mm o.c. |