Hollow Core Slabs

High strength. Low weight. For longer spans.

Hollow core slabs. For longer spans.

Jackbilt hollow core slabs offer reduced volume and weight while maintaining adequate section properties and strength.

To support hollow core slabs, you can reduce the number of columns or beams or use smaller-sized columns.

Possible Ceiling Finish

Hollow core slabs are directly paintable.

No need for drop ceilings.

No need for drop ceilings.

Typical Applications

Jackbilt hollow core slabs are ideal for longer spans and are best suited for structures that require wide open spaces like parking garages or malls or building sections like lobbies.

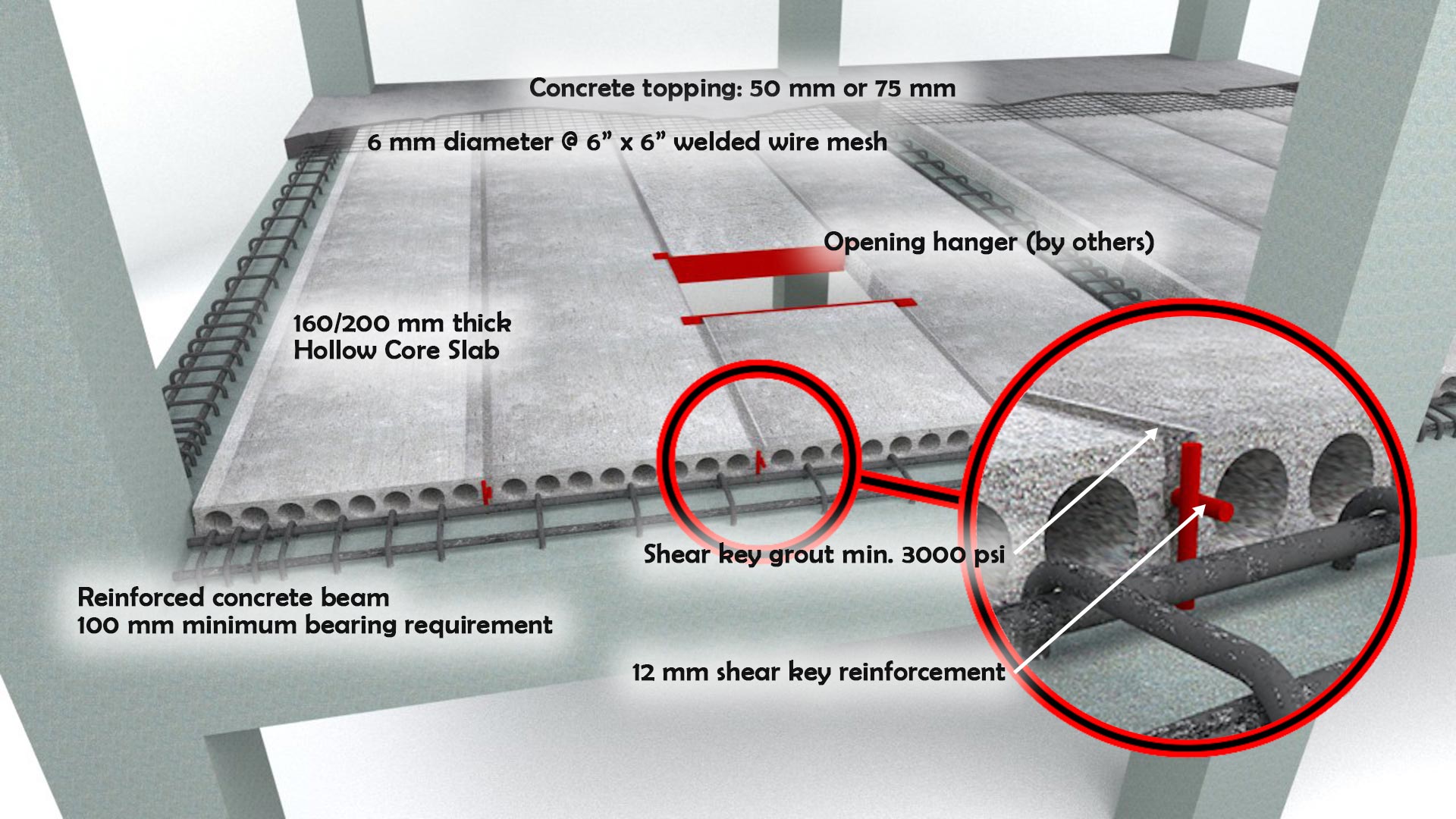

Technical Specifications

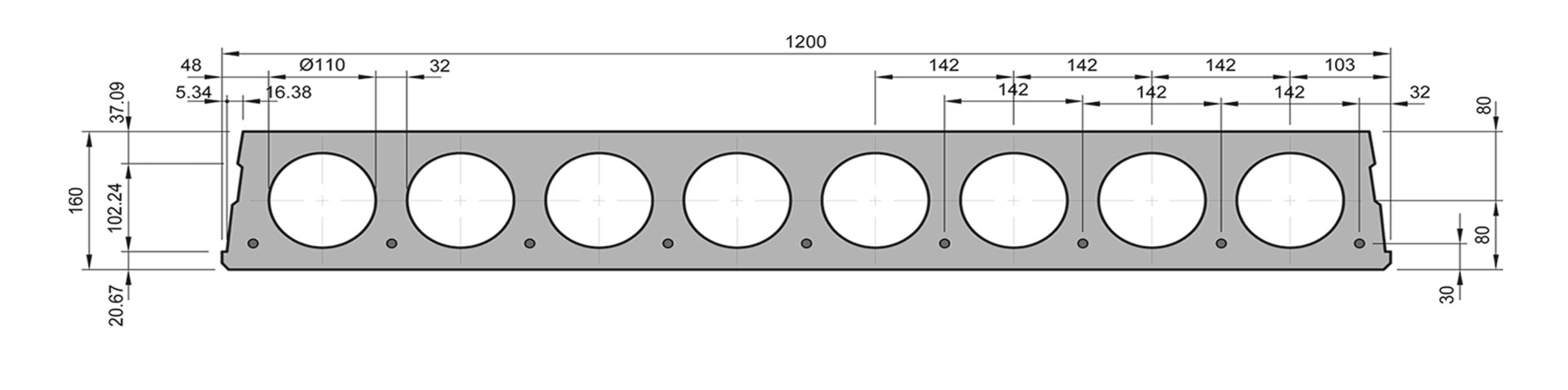

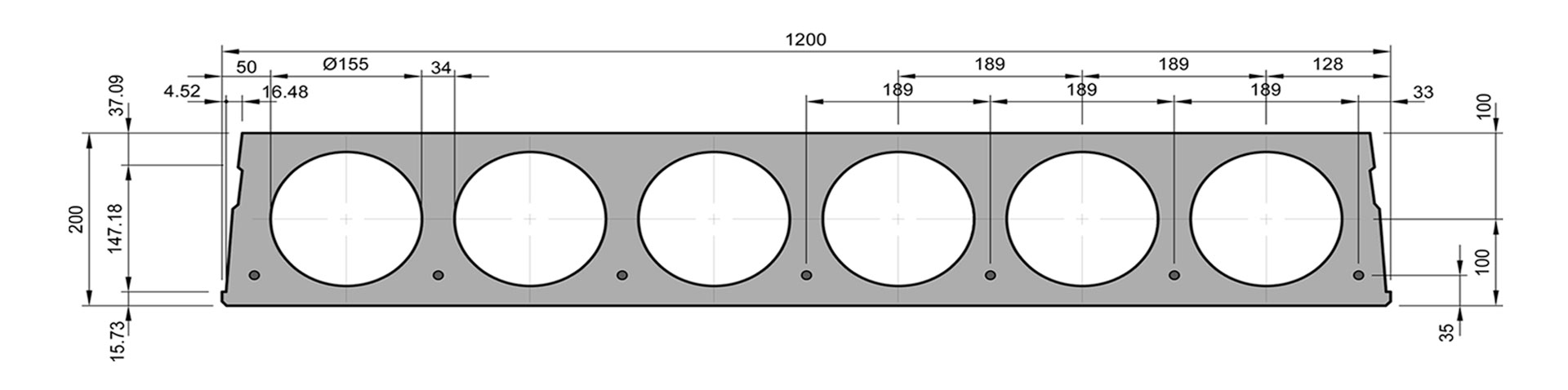

Hollow Core Slab Cross Section

| CROSS SECTIONAL PROPERTIES | HC 160 | HC 200 |

|---|---|---|

| Width mm | 1,200 | 1,200 |

| Thickness mm | 160 | 200 |

| Cross section net area mm2 | 111,925 | 121,998 |

| Distance, top fiber to neutral axis, mm | 80 | 100 |

| Distance, bottom fiber to neutral axis, mm | 79 | 100 |

| Moment of inertia, mm4 | 328 x 106 | 568 x 106 |

| Self weight of product, kg/m2 | 224 | 244 |

| CONCRETE PROPERTIES | HC 160 | HC 200 |

|---|---|---|

| Concrete density, kg/m3 | 2,400 | |

| Strength @ 28 days, MPa | 41 | |

| Strength @ release, MPa | 27 | |

| Modulus of elasticity @ service, Ec, MPa | 30 x 103 | |

| PRESTRESSING STEEL | HC 160 | HC 200 |

|---|---|---|

| Wires | 7 wires, high tensile, helical strand | |

| Ultimate strength, fpu, MPa | 1,860 | |

| Yield strength, fpy, MPa | 1,630 | |

| Modulus of elasticity, Ep, MPa | 195 x 103 | |

| Nominal diameter mm | 9 | 12 |

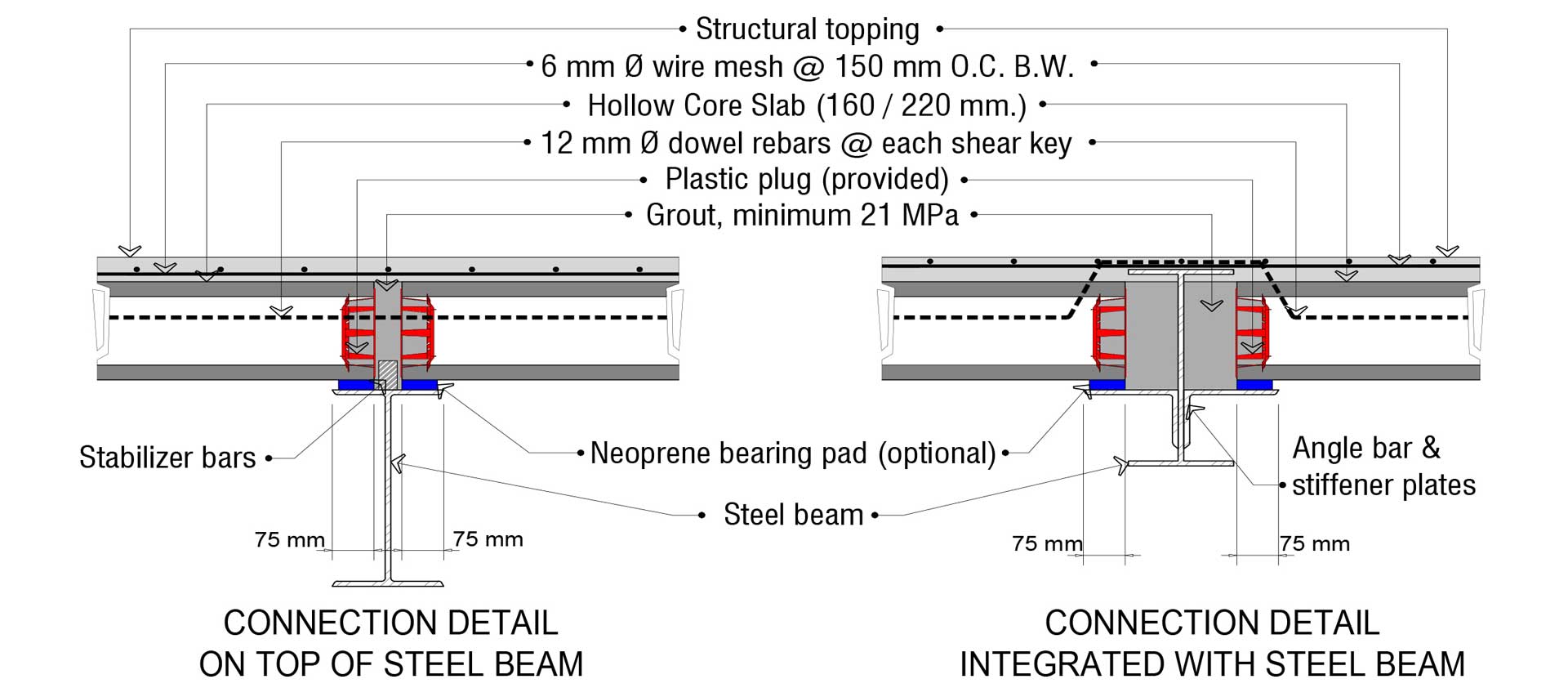

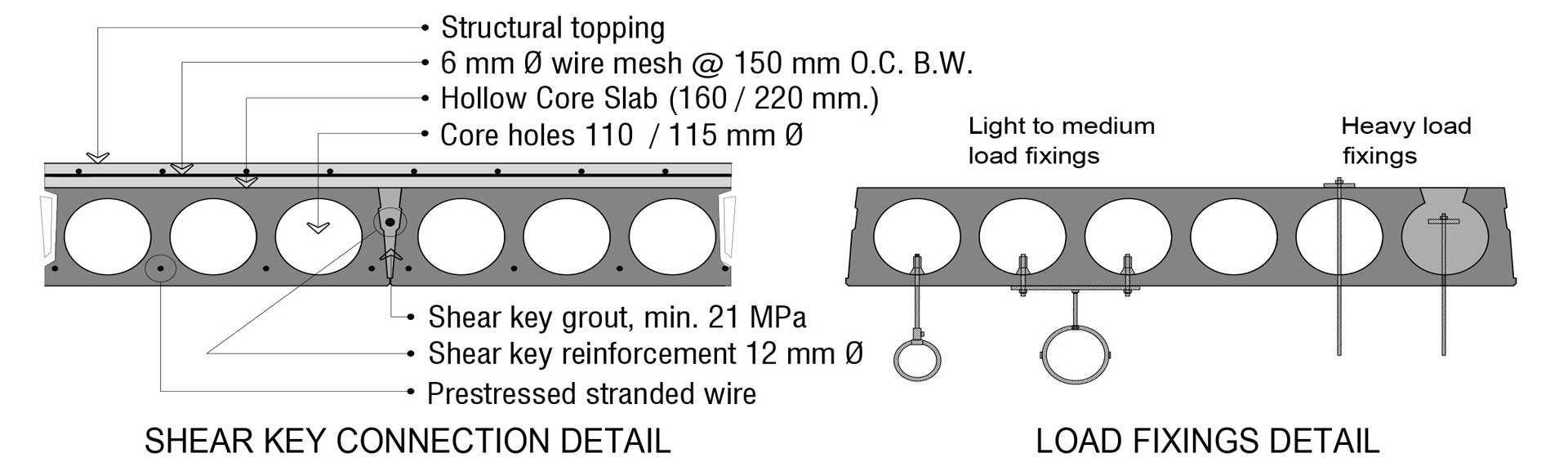

| CONCRETE TOPPING | HC 160 | HC 200 |

|---|---|---|

| Structural topping, minimum strength @ 28 days, f'c, MPa | 21 | |

| Minimum thickness mm | 50 | |

| Wire mesh reinforcement: 6 mm diameter at 150 mm o.c. | ||

Hollow Core Slab

Typical Installation

Handling

Hollow core slabs require a lifting beam and lifting clamps.

The slab must be in a horizontal position during lifting.