Inquire about Jackbilt Concrete Products

Stronger Faster Better

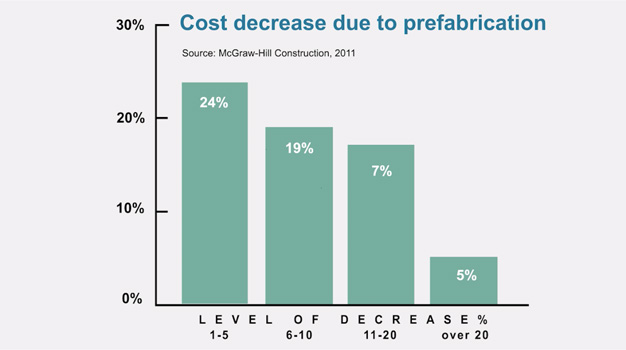

We are a pioneer and the leading manufacturer of concrete products in the Philippines. We pioneered the manufacturing of load bearing hollow blocks in 1948 using world famous machines from overseas. Our company was the first to manufacture precast & pre-stressed flooring systems like T-Joist (T- Beams), Ribbed & Half Slabs, and Hollow Core. We also manufacture precast J-Wall Partition Walls that can be 7 times faster than traditional block work. The use of JackBilt concrete products ensures at least 20% savings in cost and time.

Jackbilt Concrete Products

J-Wall Partition Walls

- Easy to install, lightweight, non-load bearing precast partition walls

- Reduce material and labor costs

- Up to 7 times faster – a team of workers using J-Wall panels can finish a wall in less time than an equal number of workers using traditional construction methods and ordinary hollow blocks

Built with Jackbilt. See our finished projects.

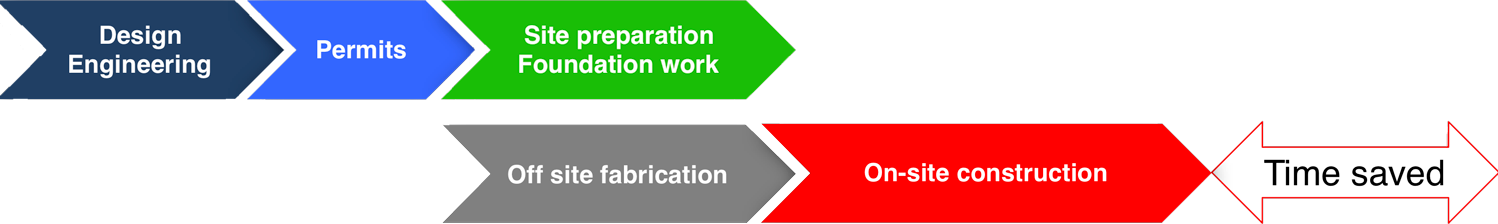

Industrialized Construction.

The way forward.

Lessen. Reduce. Save.

PRECAST. PRESTRESSED. PREFERRED.

BUILD SUSTAINABLY

Jackbilt precast slabs, walls, T-joists, and modular blocks lessen the number of materials – wire, rebar, cement, and aggregates – you need to keep in stock and manage on site and reduce the frequency of deliveries.

Jackbilt precast also decreases the amount of waste your site generates and the number of times you need to haul it away. Your jobsite won’t be adding to the amount of spent plywood forms that end up as landfill.

Lower Carbon Footprint